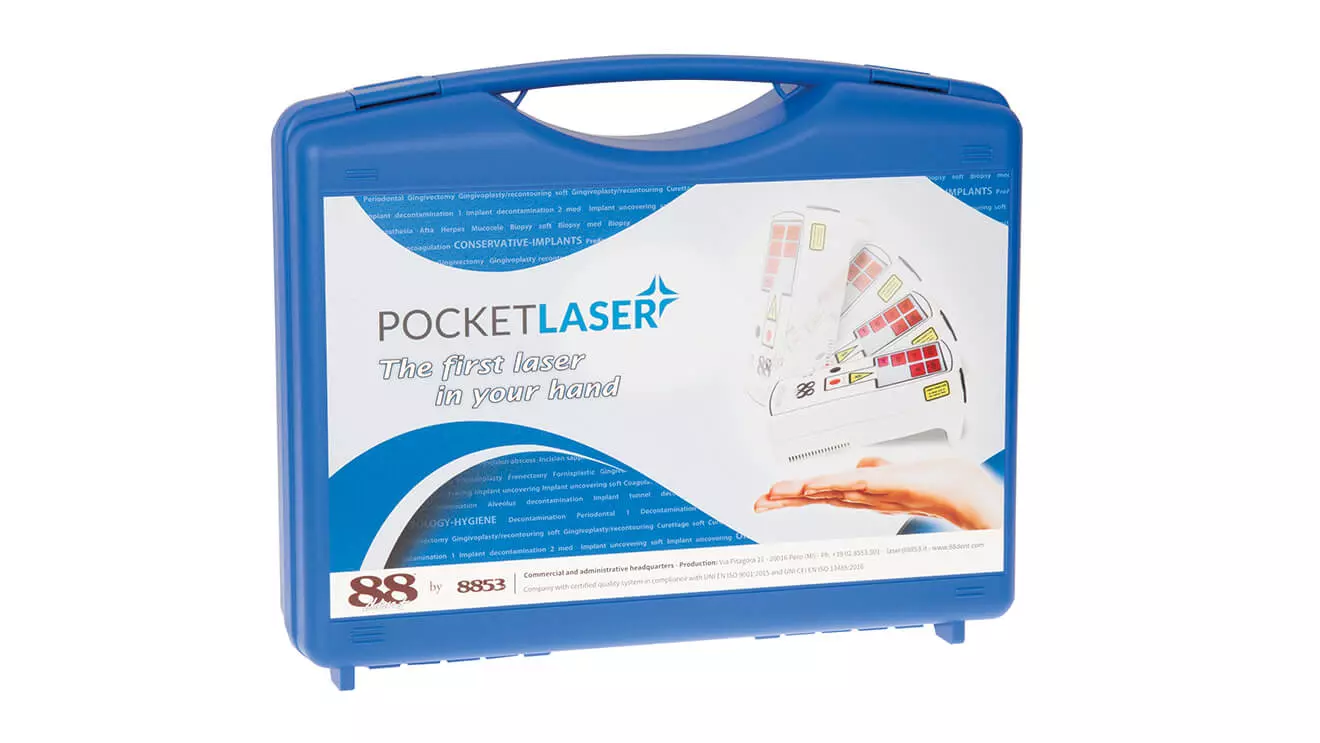

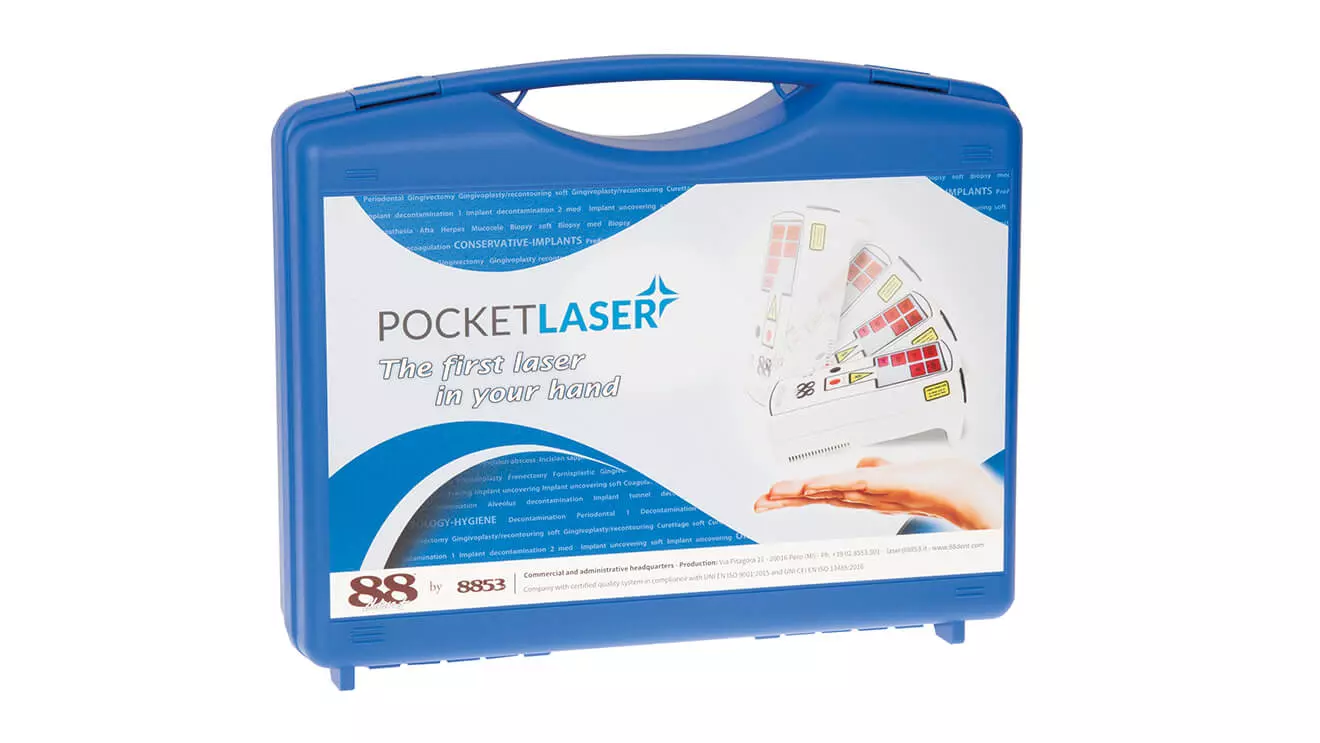

Complete customisation

Whether transport cases, sales or presentation cases, briefcases, business trolleys or promotional items for your top customers: We print your high-quality W.AG case with your own motif using classic screen or pad printing, digital direct printing or brilliant in-mould labelling (IML). The integration of Digimarc is also possible with IML: you can conveniently access a stored website directly via an app – with a guaranteed wow effect!

Case printing at W.AG has strong advantages

- Imprinted logos, advertising messages and your own photos create attention and trust in your company and your brand.

- Illustrations of the contents or instructions for use on the outer shell increase functionality.

- High-quality and durable printing with screen or pad printing, digital printing or IML, the top class among printing processes.

- Optional integration of Digimarc with IML printing for convenient retrieval of information via app.

- Customised design of the case fasteners with logo imprint or logo embossing.

- Complete handling of the pre-press stage by W.AG.

- Detailed advice from our experienced consultants by telephone and on site.

- Top service including the production of sample cases.

Case printing for your branding

Take advantage of the marketing opportunity for your company and print your cases and fasteners with your logo, a slogan or emotionally appealing photos and images in a customised and effective way. No matter where the journey takes you, your message will attract attention and be conveyed to potential customers. Your company and your brand will become better known, ensure recognition and create trust. The impressive brand presentation with your customised design is long-lasting, as our plastic cases are of high quality and particularly durable.

Printed cases increase functionality

You can increase the functionality of the case with appropriate printing. Printing the instructions for use for the products inside is not only practical, it also saves costs as well as time and effort for searching if this important information is lost. With case printing, this can never happen because the instructions are inseparable from the outer shell. The illustration of the contents on the outside also serves as an attractive presentation and can, for example, make it easier to find the relevant products.

Have suitcases printed - a wide range of options at W.AG

We offer four different printing processes for our large selection of cases and boxes. We will be happy to advise you in detail and recommend the most suitable process for your purposes. We focus on every detail! Whether it’s clever Digimarc technology, printed case latches or engraved foam inlays: we will give your company an effective appearance.

Have cases printed with screen printing

Screen printing is ideal for single and multi-coloured logos, word marks and product information. Case shells and case sides of all W.AG cases can be printed with this popular process, high-gloss and matt surfaces as well as textured plastics. Our experienced employees take care of the pre-press stage and match your colour requirements to the RAL system. You can look forward to durable printing on your cases in strong, radiant colours using classic screen printing!

Case printing with pad printing

Pad printing is used on small printing areas such as clip fasteners and on the narrow sides of plastic cases and plastic boxes. The process is ideal for single and multi-coloured motifs, can be used on all W.AG cases and achieves high colour intensity. Examples of high-quality cases with pad printing motifs can be found here.

Printing on cases with digital direct printing

Four-colour digital printing is ideal for sophisticated motifs in photo quality, graphics and colour gradients. W.AG uses it to create eye-catching prints on plastic cases and boxes, primarily for samples and for small quantities of personalised cases. Digital printing on transparent half-shells is particularly attractive. You can rely on our pre-press department to advise you in detail on the design and carefully check your print data before printing begins. We will be happy to inform you about the process in person or on our digital direct printing page.

In-mould printing for maximum brilliance and durability

In-mould labelling (IML) stands for high-end case printing. This process achieves brilliant photo quality and impresses with high UV and abrasion protection as well as high resistance to temperature fluctuations and moisture. During the production process, the printed motif film merges with the surface of the case to form an inseparable unit. The label neither peels off nor can it slip. We recommend IML for brilliant photo motifs and maximum durability, even for large quantities. The production process is surprisingly cost-effective. Do you value sustainability? IML film can be completely recycled, just like all our plastic cases and boxes. We would be happy to advise you in detail on the subject of in-mould labelling!

Have suitcases printed with Digimarc

Digimarc is the name for a barcode that is invisible to the eye and can be scanned using an app. The code is printed on the case as a digital watermark and leads via a link directly to a website with content provided by you. The overall appearance of the case is not spoilt by distracting QR codes, while the digital technology offers maximum convenience and provides useful and interactive content for your employees and customers. The practical tool can be integrated into the IML printing process. For more information, please contact us or visit our Digimarc page.

This is what we stand for

Ready for innovation?

Contact us