Foam inserts

Whether measuring devices, tools, cameras or hardware: with the case inserts from W.AG, you are guaranteed to get even sensitive parts safely to their destination. After all, the recesses in the inserts give the items being transported support and stability, keep them organised and also look damn good.

Customised case inserts for individual requirements

They can be laser-engraved with your brand logo or special labelling to present your company or product professionally during transport. As plate foams in a bright blue or red colour, they create a wow effect when the case is opened and draw attention to your presentation items. Our foams are also available in a sustainable version. We will be happy to inform you!

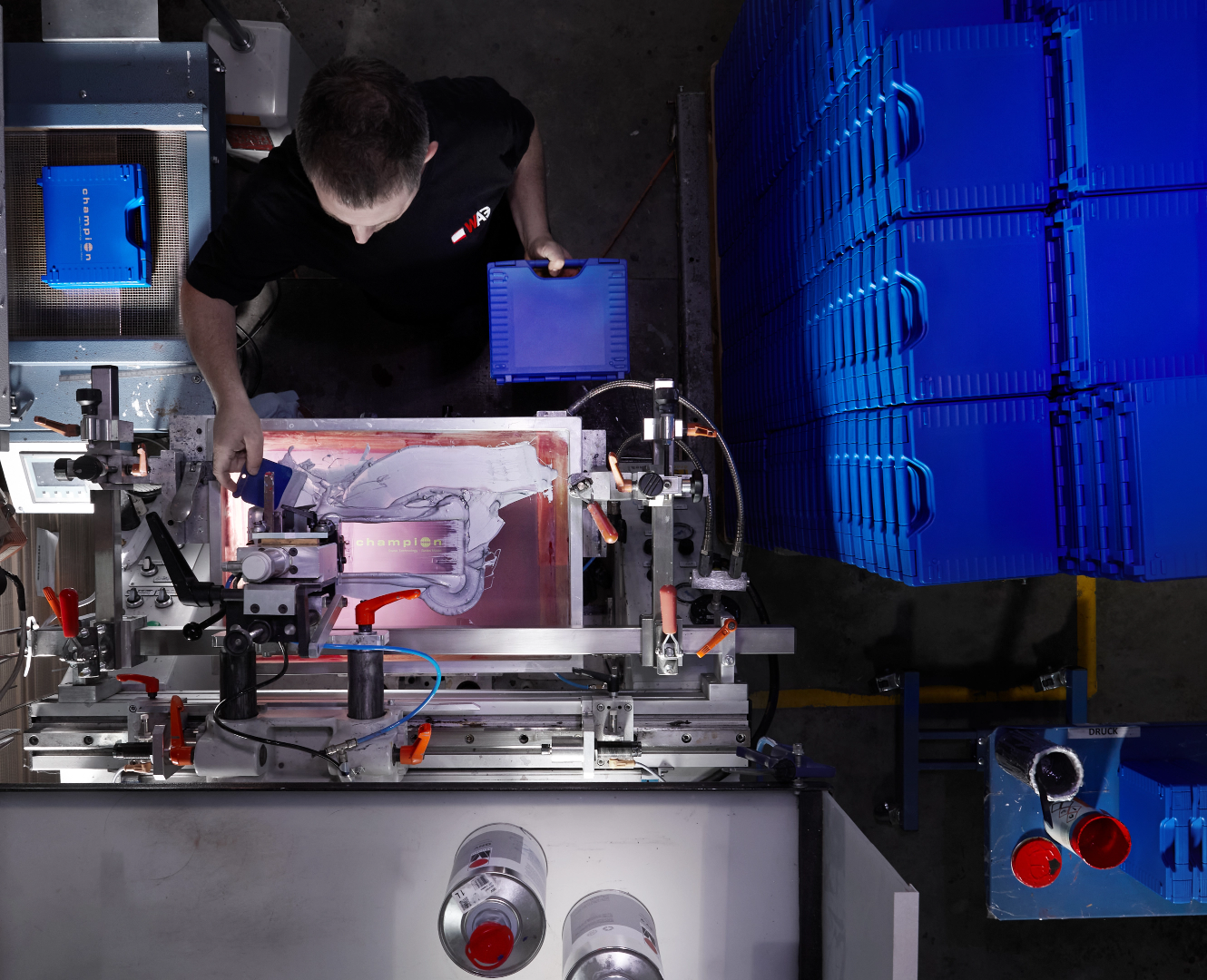

Innovative foam processing from a single source

As a manufacturer of foam inserts, we are in demand twice over: in the development of customised case inserts and in the subsequent production. Our experienced development team places particular emphasis on optimising product safety, an attractive presentation and a high level of user-friendliness in addition to a space-saving arrangement of the contents. This is made possible by comprehensive personal consultation and the exact determination of the respective product specifics. The individualised processing of the foam is carried out by milling, water jet cutting or laser cutting in our state-of-the-art machinery. Laser engraving is also possible as an option. Raster foams for surface protection are punched.

Hard foam or soft foam

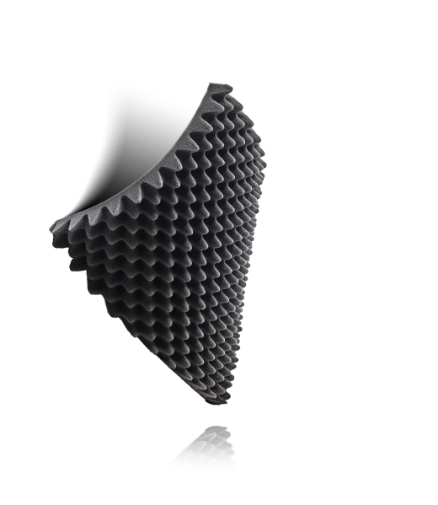

Which foam inlay would you like? Tool inserts; foam inserts for drills, helmets, spanners or projectors; inlays for promotional gifts or wristwatches – you decide what your case foam should look like and what functions it should fulfil. Depending on the packaged goods, our cases can be fitted with inserts made of PE rigid foam or PU flexible foam. These include PU studded foams as well as sheet foams, water jet parts and milled inserts, which are customised to the height and application of your products. We would be happy to advise you in detail about your options and provide you with a quote. Discover our rigid foam inserts and flexible foam inserts now.

Polyethylene (PE): The all-rounder in the packaging industry

Foam inserts made of polyethylene (PE) are by far the most frequently used inlays for suitcases, as is the case at W.AG. After all, the material is easy to process and can be easily moulded into individual foam inserts using various processes. It is available uncross-linked, cross-linked and extruded and is characterised in all types by its chemical durability, good sliding behaviour and high electrical insulation. Due to their high resistance to chemical substances, non-crosslinked PE foam inserts are increasingly used in medicine and pharmacology or as shock absorbers for heavy loads, for example in our HEAVY heavy-duty case.

Polyurethane (PU): The lightweight among foams

Flexible PU foams have a low dead weight and are permanently elastic and air-permeable thanks to their open cell structure. They can be easily and reversibly moulded, absorb shocks and are particularly suitable for the safe transport and protection of light and fragile goods such as glass or ceramics.

Thermoformed inlays as another inlay solution

As an alternative to our foam inserts, thermoformed inserts are available in various colours, materials and surfaces, which can also be engraved. In addition to the standard colours, we can also produce special colours on request. Whether a foam or thermoformed insert is the perfect fit depends primarily on the nature of the packaged goods and the customer’s requirements. Thermoformed inserts with a smooth surface are particularly suitable for items or devices that require disinfection, for example in medical technology.

Do you have any questions?

Get in touch now