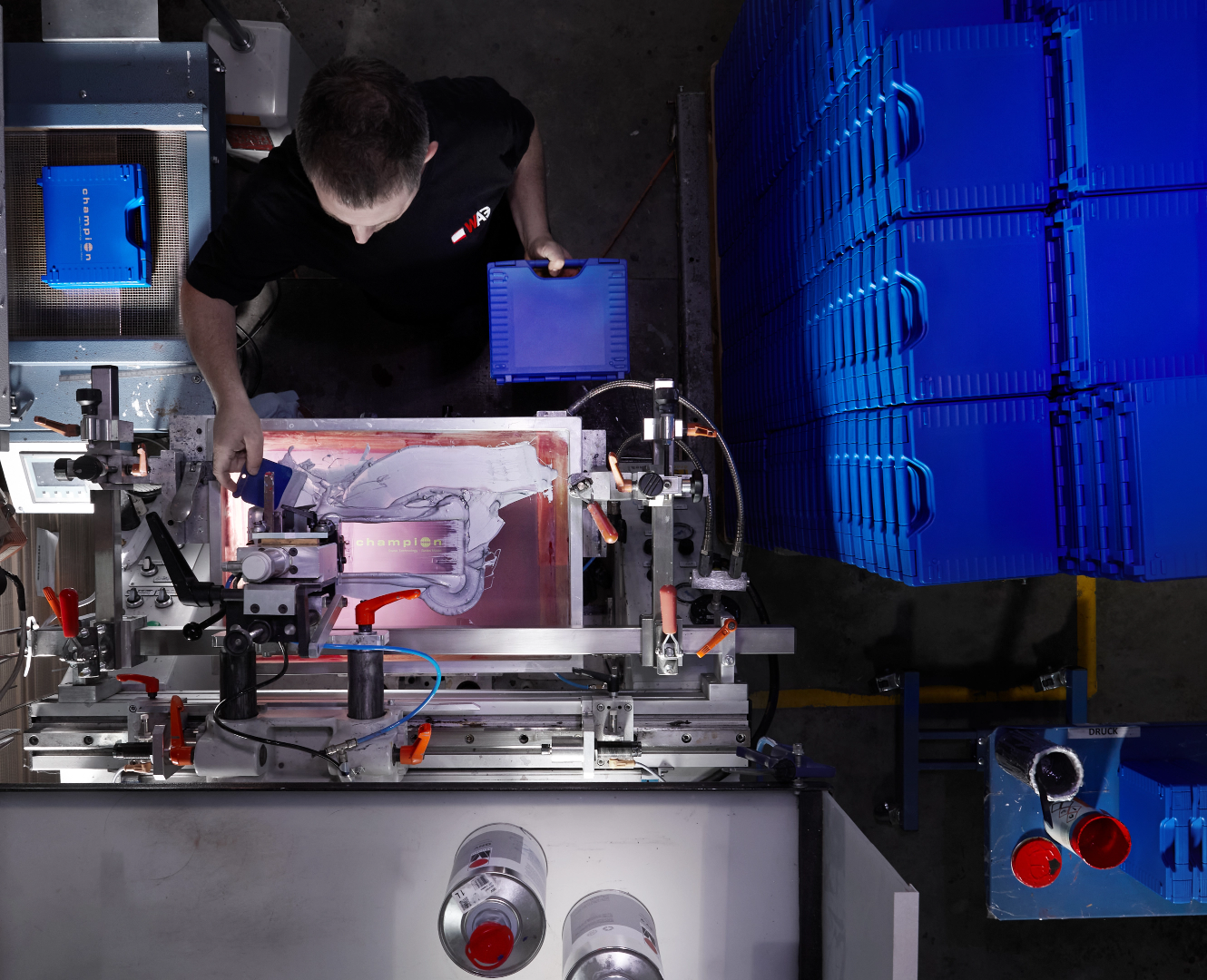

Precise cutting of the inlays

We produce water-blasted inlays, milled inlays and classic, punched nub foams. As an alternative to traditional foam inlays, we offer thermoformed inlays – the advantage of which is that the surface can be wiped clean. We ensure efficient placement of the parts in the case. After all, the case should be as small as possible. We make sure that every part can be easily removed and put back and is optimally padded and protected. You tell us what you want to store in the case and we take care of everything else. We are your personal configurator!

Cases - inlays with their own design language

Many offer precisely cut foams – we also offer customised design: milled logos and lettering make an impression as soon as you open the lid and support brand recognition. They can be milled into both foam inlays and thermoformed inserts.

Inlay features for more organisation

We recommend our matching cardboard pockets with a window for storing business cards, brochures, operating instructions etc. safely and within easy reach. They are available either open at the top, with a flap or magnetic clips.

Ready for innovation?

Get in touch now