What are deep-drawing insoles?

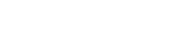

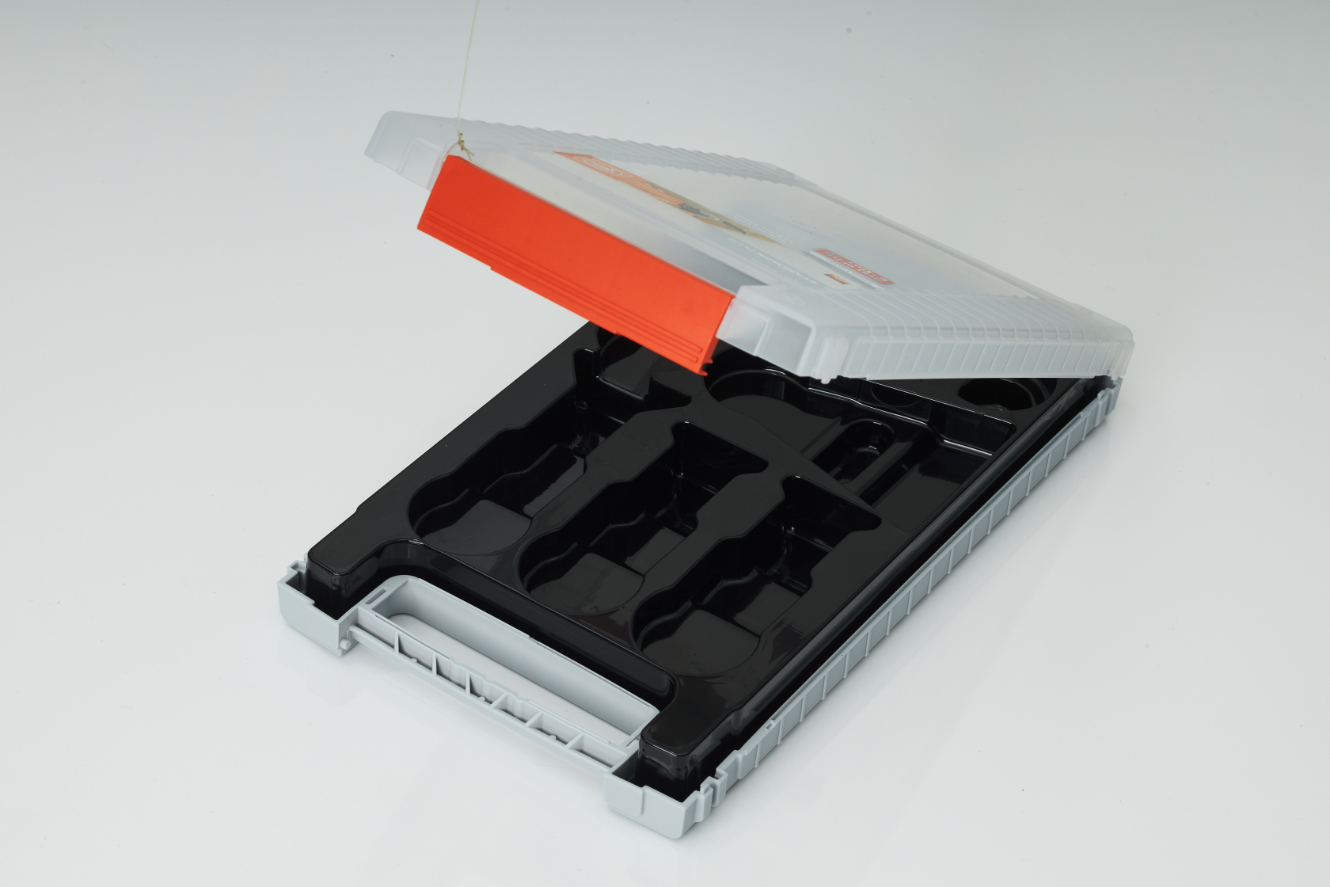

Thermoformed inserts are specially customised inserts for suitcases. They consist of plastic sheets that are first heated and then moulded. This results in custom-fit inlays that are optimised for the respective case interior and the items stored inside. Thermoformed inlays are particularly robust and durable packaging that is easy to clean.

What are thermoformed insoles suitable for?

They are the best choice as inlays for cases when special hygiene requirements need to be met. As the inlays are very easy to clean or even disinfect, cases with deep-drawn inlays are valued in many industries. The inlays adapt perfectly to the shape of any object and thus offer a safe transport option for various goods, e.g.

- Medical technology

- Measuring instruments

- Tools (non-medical)

- Small parts

What are deep-drawing insoles not suitable for?

Although thermoforming inserts are solvent-resistant, they are not considered to be pressure-resistant and they do not cope too well with high temperatures. They are therefore not suitable for

- Sensitive goods

- Glass

- Porcelain

- Due to the low impact resistance and elasticity of the plastic, we recommend soft foam inserts for the packaging and storage of these goods.

What types of thermoforming insoles are available?

We offer a wide range of options for customising the plastic case inlay and adapting it to your specific requirements. We manufacture the thermoformed inserts from different materials and can realise different surface qualities:

- Smooth surfaces

- glossy surfaces

- grained optics

What colours are thermoforming inlays available in?

Unlike inserts made of PU or PE foam, we can manufacture thermoformed inserts in individual colours. The most popular standard colours are white, black, silver, grey and transparent. Of course, we can also design the plastic insert creatively and match it to the colours of your corporate design, for example – special colours are easily possible.

Can logos be embossed into thermoformed inserts?

In addition to their high quality, thermoformed inserts score points with their versatility – this also applies to the processing options. On request, it is possible to customise the plastic with your logo. This allows you to emphasise your professionalism at every presentation. Additional labelling is also possible – for example, you can use this to keep the contents of small cases more organised or provide the case user or their employees with helpful instructions.

How sustainable are thermoformed insoles?

As a manufacturer of plastic packaging, we ensure that our production processes are as resource-efficient as possible and that we use high-quality, durable materials. The material we use in the thermoforming process is extremely robust, easy to clean and can be used several times. If you have even higher requirements for your case inlay, we recommend our sustainable inlays from the ORGANICLINE series. These are made from renewable raw materials and can be completely recycled.

Do you have any questions?

Get in touch now