What are soft foam inserts?

Soft foam inserts are used as inlays in suitcases for padding and are made of polyurethane. This is an elastic foam material that allows the case to be softly padded. Soft foam inserts are particularly suitable for transporting fragile items such as lights and glass, as they are mouldable and therefore reliably absorb pressure and shocks.

Hard foam inserts for cases in many designs

- Customised production

- Processing with water jets, lasers or milling

- many qualities in stock

- Customised solutions

- customised embossing & engraving

- Sample inserts

What are soft foam inserts suitable for?

An inlay made of soft PU foam is always required when fragile objects that are sensitive to shocks need to be transported and/or presented without damage, e.g:

- fine glasses,

- precious ceramics,

- valuable works of art.

They are all packed safely and attractively in flexible foam. The high elasticity of the foam ensures optimum cushioning. This means that the packaged items are only slightly affected by impacts. The foam is heat-resistant, harmless to health and sound-absorbing – which can be practical when transporting glass objects, for example.

What are soft foam insoles not suitable for?

Soft foam inserts are less resistant to chemical substances than comparable hard foam inserts. The material is therefore not suitable for storing or transporting such items. The same applies to items that need to be secured under special hygienic conditions – it is not easy to disinfect the inlay as PU foam is not resistant to solvents.

Also important: Due to the high elasticity, the objects that are embedded in the soft foam should not be too heavy. Otherwise, the inlay may become too deformed, reducing the protective effect.

What types of soft foam insoles are available?

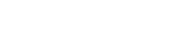

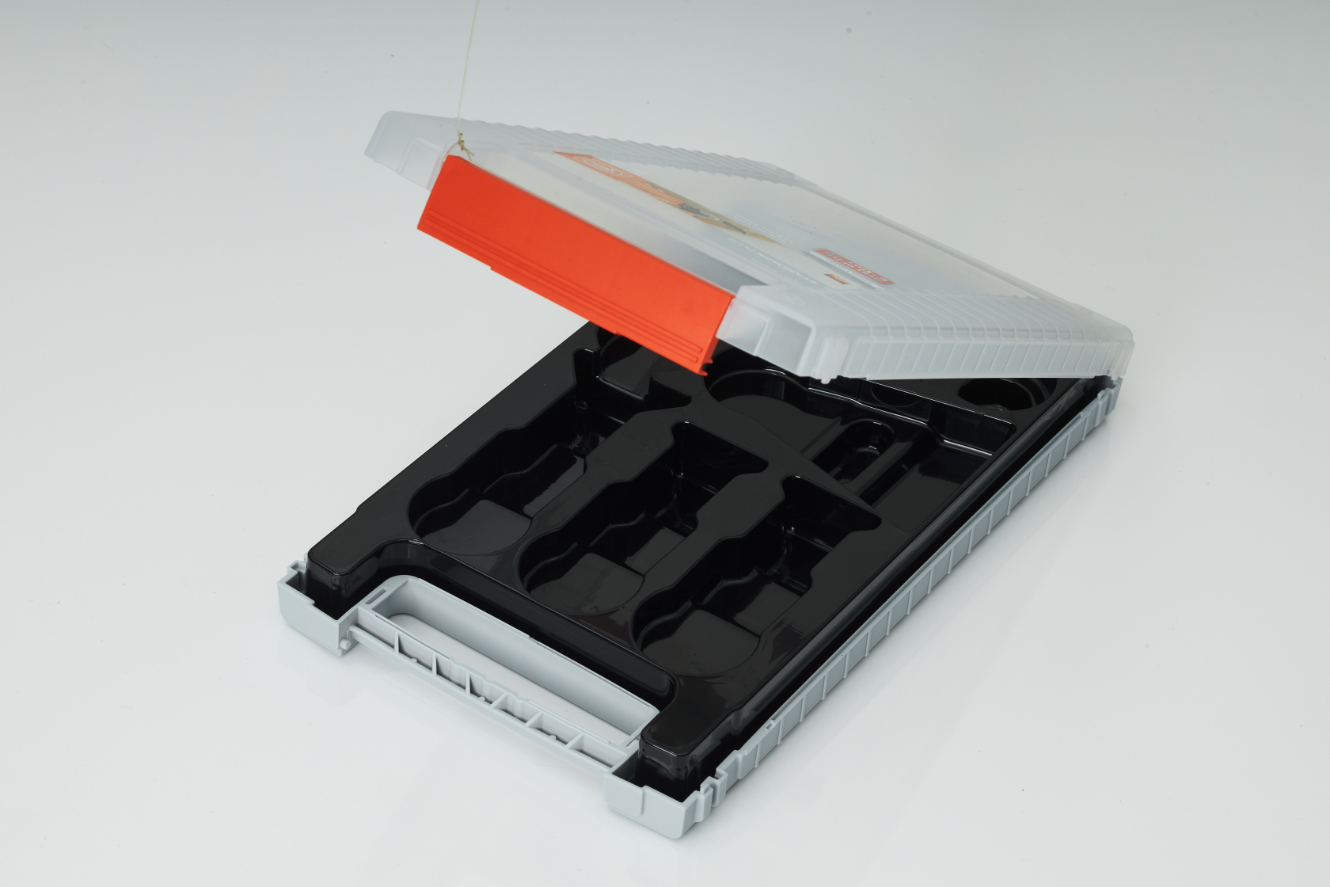

We customise soft foam inserts for each individual case. There are differences mainly in terms of structure: we process soft foam with a smooth surface (PU 90 025) as well as PU nubbed foam in two different versions. The latter is often used for the fittings of case lids – often in combination with deep-drawn inserts or hard foam inlays.

What colours are soft foam insoles available in?

The range of our classic soft foam inlays includes the colours dark grey and black – for a discreet, elegant and serious impression. You can discover a wider range of colours in our rigid foams and sustainable foam inlays made from renewable raw materials.

How sustainable are soft foam insoles?

Flexible foam inserts are very resistant and robust. This makes them particularly durable, which reduces production costs and minimises waste. Our innovative soft foam inserts for tools and other items made from renewable raw materials from the ORGANICLINE range are even more sustainable. These are not only produced using a particularly resource-saving manufacturing process, but are also fully recyclable. In terms of versatility, these inserts are in no way inferior to classic flexible foams.